Consideration of temperature and humidity in the processing of fiber-based materials

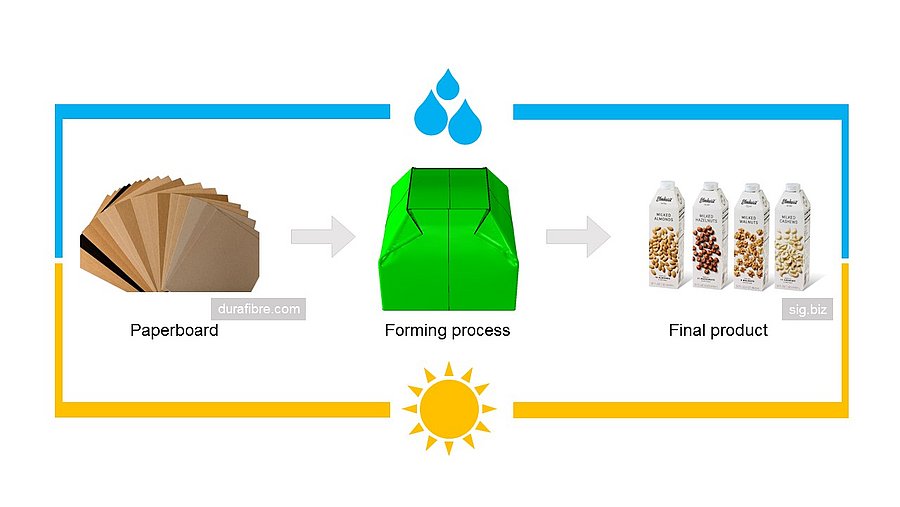

The steadily increasing environmental awareness leads to an expansion of the application field of paper and cardboard. Especially in the packaging industry, properties such as degradability, recyclability and reusability offer paper and cardboard products a clear advantage over petrochemical packaging materials. Sensitivity to moisture, barrier properties and formability are three main factors that lead to lesser use of paper and cardboard in demanding packaging solutions. In particular, the difficulty controlling the influence of moisture during transport and storage poses a considerable problem for later processing. The lack of possibilities to control environmental conditions in all production and storage facilities and to adjust the machines/tools appropriately prior to the forming process, motivate the use of simulations.

The aim of the project is to develop a proficient simulation tool, capable of assessing the complex material behavior of paper while taking humidity and temperature into account. Therefore, a fully thermomechanically coupled material model is derived and implemented into a FEM program. In the material model framework, humidity is defined as an internal variable evolving in time in dependence of temperature. Extensive experimental investigations in combination with microstructure modeling are intended for determining the mechanical and thermal/hygroscopic properties. With the gained knowledge, the material model is to be calibrated and optimized. Finally, the material model is to be validated by simulating a practically relevant forming process.

The intended project goal should result in an increasing potential of paper and cardboard utilization, provide those involved in the packaging industry with a better insight into the material behavior and enable a more efficient use of existing forming processes and the development of new ones.