Digital platform for the production-related design of sustainable lightweight composite materials based on wood fibers

ikea.com

kurtmueller.com

pmv.tu-darmstadt.de

sig.biz

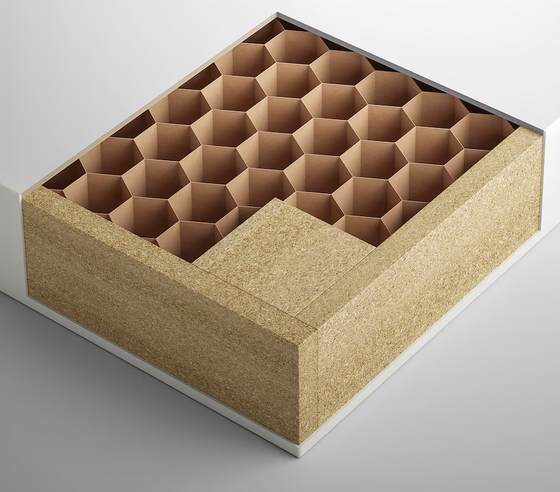

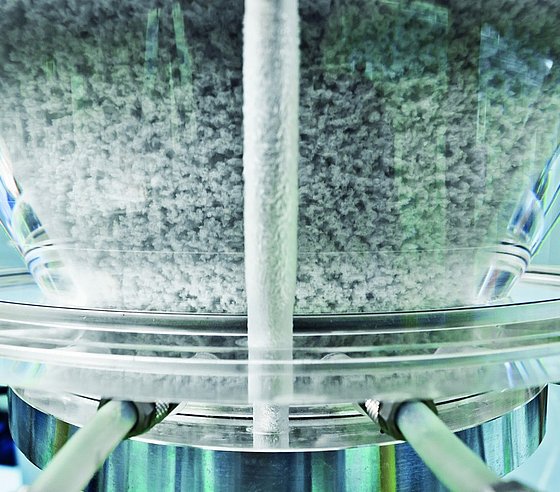

The paper and paperboard processing industry in Germany is a branch with approximately 84,000 employees and annual sales of around 19 billion euros in 2019. Contrary to widespread use, industrial processes still rely mostly on empirical methods. In order to meet the current and future demands of sustainability and to remain internationally competitive, it is essential to considerably increase the material utilization of paper and paperboard. Here, precise knowledge of the mechanical properties of the microstructure and its influence on the macroscopic material behavior is crucial. Based on the actual fiber orientations, fiber densities, and ply structure and taking into account the statistical variations, it should become possible to guarantee the required component properties (here packaging, membranes, honeycomb core structures) in a resource-efficient manner.

In the subproject at the University of Wuppertal, the fluctuations in fiber networks of paper and paperboard are to be investigated by simulating corresponding microstructures. The respective stochastically varying material parameters are then included in a macromechanical material model, which allows the calculation of manufacturing and forming processes. In order to improve the macromechanical behavior, possible improvements for the microstructures, such as the adjustment of fiber orientations, are developed.