A novel direct method for predicting failure of particle reinforced metal matrix composites

Metal matrix composites (MMCs) are a type of composite material that combines a metal matrix with a reinforcement material, such as fibers, particles, or whiskers. The metal matrix provides the structural integrity and mechanical properties, while the reinforcement material enhances the composite's strength, stiffness, and thermal conductivity.

Metal matrix composites have a broad application field due to their excellent mechanical, thermal, and surface characteristics. For example, they are suitable for the electronic, automotive, aerospace, and robotic industrial sectors. In 2019, the global metal matrix composite market size was valued at almost 340 million USD. Particularly the automotive and aerospace sectors are anticipated to drive the market for metal matrix composites even further over the coming years, because of the increasing need for fuel-efficient lightweight components. Despite the relevance of these materials, their material behavior is not yet fully understood and the existing models are underdeveloped in terms of plasticity coupled to damage, fatigue, and limit states. One reason for that is the complexity of the material behavior, which results from its multiscale nature, since the composites macroscale response is dictated by the intrinsic microstructure.

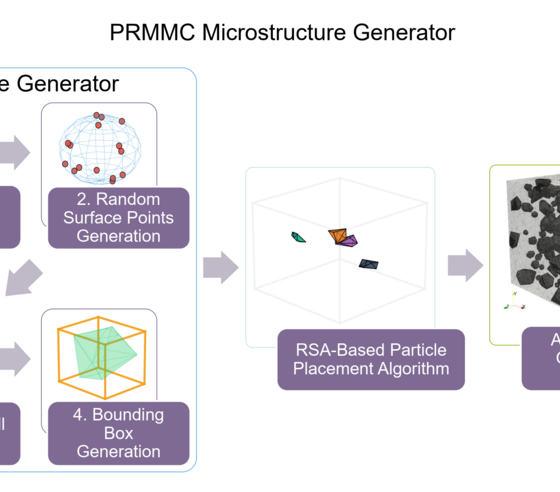

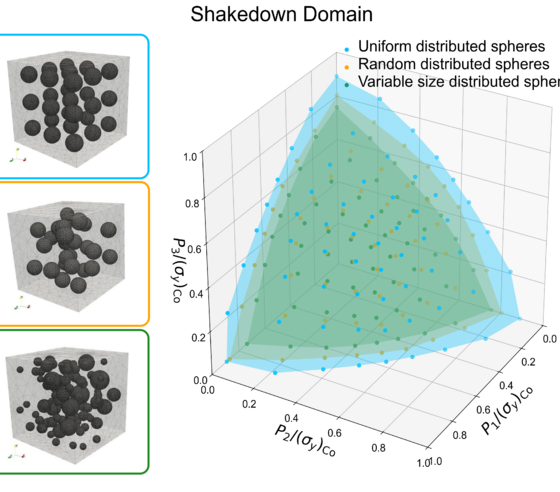

In this work, we focus on particle reinforced metal matrix composites (PRMMC), whose failure mostly depends on the particle size, volume ratio, and particle distribution. In order to expand the practical applications of PRMMC, it is necessary to gain a deeper understanding of the material behavior and to implement this understanding into a numerical multiscale modelling framework. This framework will enable the determination of limit states of composite structures, ensuring that they remain safe even under complex and varying loading scenarios.

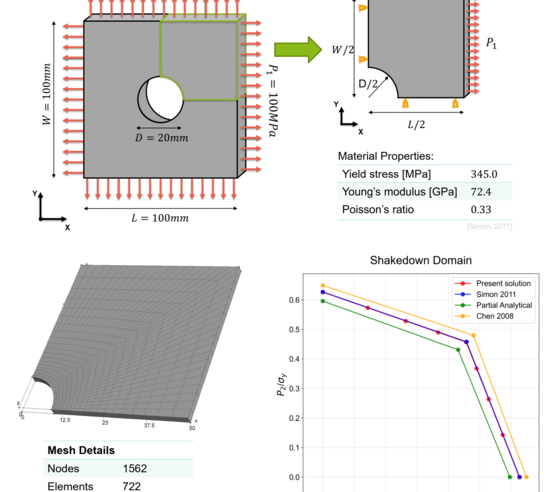

The objective of this project is to develop a framework for limit state analysis that will include plasticity with nonlinear hardening, ductile matrix damage, brittle particle cracking, particle-matrix debonding, and also incremental plastic collapse and alternating plasticity. So far, these phenomena have been treated as distinct entities, employing either incremental methods that follow the given load-path step-wise for the former or path-independent direct methods that consider only the final failure states for the latter.

This project departs from traditional methods and aims to integrate these phenomena within a unified direct method implemented in a unique computational tool. The result is a novel direct method for predicting the failure of advanced composite materials under complex loading states and deformation histories. Consequently, the damage states can be considered by a direct method without the necessity of conducting incremental analysis, at least during the initial phase of structural design, where precise knowledge of damage patterns is not required. This represents a paradigm shift that will facilitate the development of novel engineering design concepts for composite structures.