Understanding and Predicting the Failure of Cellulosic Materials

Paper and paperboard are gaining importance in numerous technically relevant applications because they are extremely versatile, renewable materials and easily recyclable. Nevertheless, its material behavior is still not sufficiently understood, and its modeling is underdeveloped. The challenge in the material modeling of paper is its multiscale nature. On the macroscale, paper shows a distinct elastoplastic behavior coupled with progressively evolving damage. While these effects are well understood for engineering materials such as metals, where mechanisms like plastic slip and growing voids or cracks in the microstructure are known to result in plasticity and damage on the macroscale, such effects are drastically different in paper. The reason that paper is so fundamentally different is the intrinsic microstructure, which consists of an unstructured fiber network. This fiber network dictates the macroscale material response. The elasto-plastic behavior of single fibers, the breaking of individual fibers and fiber bonds, and friction between fibers result in what appears to be a combination of elasto-plasticity and progressive damage on the macroscale. While the presence of these mechanisms is widely acknowledged, the following two critical questions remain unanswered:

- Which of these microscopic mechanisms is/are the dominant driver(s) of the macroscopic behavior in various situations?

- How do local plasticity and damage interact to result in the observed macroscale responses?

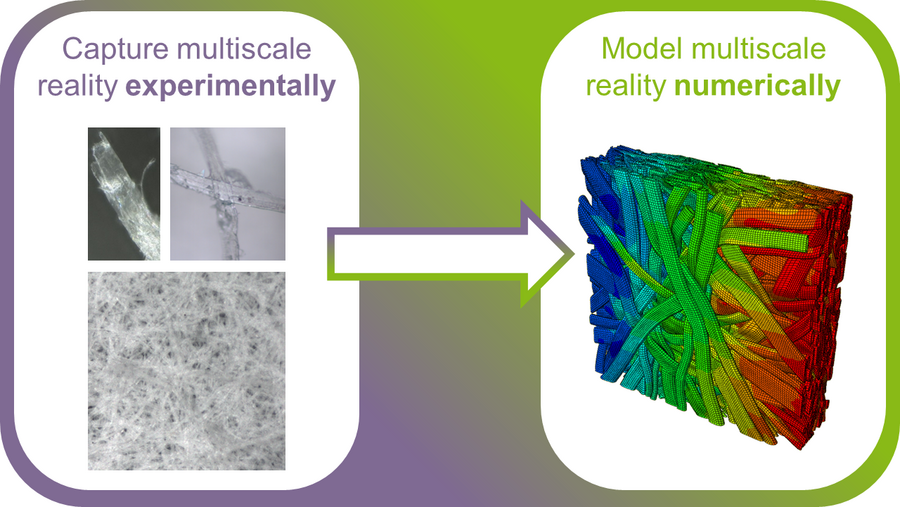

Our ambition is to scrutinize the interaction of plasticity and damage resulting from the fiber network response. This requires, first of all, a sound experimental basis on the scales of single fibers, fiber bonds, fiber networks, and sheets. Further, these mechanisms will be built into a computational tool with a view to analyzing the failure of cellulosic materials such as paper and paperboard. Addressing the critical missing links between microscopic effects and the resulting effective behavior, particularly in the context of nonlinear deformation and progressive damage evolution, will constitute a breakthrough in relation to the existing research on these materials. To tackle this challenging multiscale problem, several innovations are necessary. First, the fibers and bonds have to be calibrated to experimental data that account for the influence of microfibrils. One very promising approach in that direction is adapting the wide-angle X-ray scattering technique to fibrous materials. Further, the fiber network microstructure must be resolved accurately, and statistical variations must be included. In addition, an innovative homogenization scheme that enables consideration of damage needs to be developed. The outcome of the project will be a fully validated numerical toolbox for failure analysis so that paper-made structures can be designed for optimized structural performance.

Funding

German Research Foundation (DFG)