Modeling and simulation in road construction

Germany has an extensive and dense network of roads by international standards. Currently, this is also characterized by good quality; in an international comparison, Germany ranked ranked 22nd out of 141 in the Global Competitiveness Report 2019 . However, public investment in Germany's transport infrastructure has been inadequate for years. Various studies show that both Germany as a business location and the mobility of its citizens are seriously jeopardized by the ongoing deterioration of its transport infrastructure. In the Transport Investment Report for the reporting year 2020, the asset value of 17.1% of the federal highways was classified as poor or very poor. In addition, traffic and environmental stress will increase.

With the exception of a slump caused by the COVID-19 pandemic, traffic in Germany has increased sharply since 1990 and before, with heavy vehicles on freeways in particular increasing many times over. A recent study predicts a further increase of 54% in road freight traffic between 2019 and 2051. At the same time, climate change is also causing high air temperatures to occur more frequently and more intensely in Germany. The average annual air temperature in Germany has risen by around 1.6 °C between 1881 and 2021. Previous findings show that average temperatures and daily amplitudes are increasing in Germany, particularly in summer. Both asphalt and concrete construction are suffering from these increased loads. While asphalt in particular loses stability and forms ruts, concrete is subject to heat-induced deformation and fatigue.

To ensure mobility in the future, it is desirable to maximize the service life of roads and minimize maintenance costs, traffic restrictions and personnel costs. The current standard methods for the computational design of roads are essentially several decades old and their scope of modeling is limited, e.g. to linear material behavior. It is therefore necessary to develop numerical simulation models that can be used as an optimization tool for the efficient development of new construction materials, but also for the improvement of existing construction materials.

Asphalt

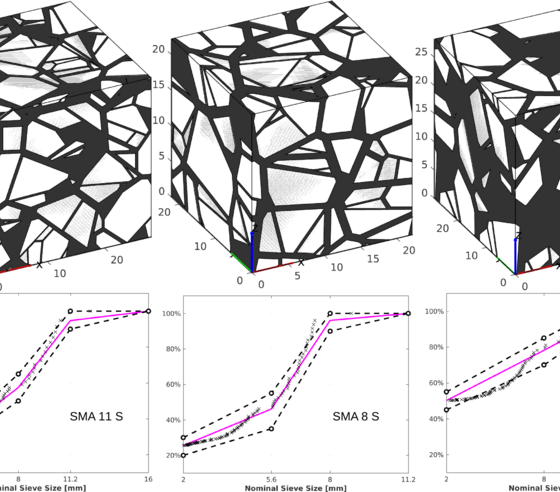

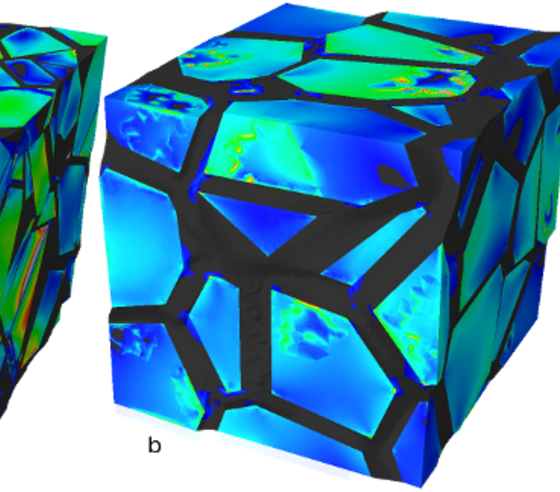

The existing work focuses on a computer-based framework for modeling and simulating asphalt surface courses on the mm scale. The grain structure of the asphalt is resolved by a modified Voronoi tessellation from the 2 mm sieve size upwards and thus enters the modeling with realistic volume fractions. The connecting bituminous mastic is modeled in a linear viscoelastic fashion. A homogenization process is used to calculate effective material properties on the macroscale. The method thus provides insight into the local load conditions in the heterogeneous material in order to improve the design of future asphalts.

Possibilities for further development (e.g. for final theses)

- Extension of viscoelastic material modeling to include plasticity.

- Investigation of the need to consider non-convex grain shapes.

- Use of massively parallel calculation on high-performance computers.

- Implementation of a 2nd order homogenization scheme.

Concrete

Particularly with high axle loads and temperatures, concrete pavements can play out their advantages of higher load-bearing capacity and deformation stability over asphalt construction, as rutting, for example, does not occur. As a result, concrete pavements are preferably used on road sections with high loads. It is known that the current consideration of the temperature loading and the bearing of the concrete slabs is not sufficient. The aim of this project is the realistic modeling of the thermomechanical behavior of concrete pavements in slab construction with current methods using white-box codes.