Integrated Computational Materials Engineering of Thermoplastic Composites

High-performance thermoplastic composites (TPCs) combine exceptional toughness, weldability, and recyclability, positioning them as promising materials for future aerospace structures. However, unlike metals or thermosetting composites, TPCs lack a comprehensive predictive framework that links processing conditions to microstructure evolution and structural performance.

This project addresses this gap by developing an integrated computational–materials framework capable of describing processing-induced microstructural changes, interfacial behavior, and failure mechanisms in carbon-fiber–reinforced TPCs. The project unites complementary expertise from Michigan Technological University and UC San Diego. Central to this network is a close, long-standing partnership with Brett A. Bednarcyk and Evan J. Pineda at NASA Glenn Research Center. Together, this unique cooperation integrates multi-scale mechanics, continuum modeling, molecular insights, and data-driven optimization.

Research Focus

-

Multi-scale & multi-physics modeling framework: Establishing a predictive description of how processing histories shape microstructure, residual stresses, and effective material behavior.

-

Interface and delamination behavior: Developing cohesive zone models to capture bonding, debonding, and mixed-mode fracture at fiber–matrix and interlaminar interfaces.

-

Damage and failure modeling: Creating a robust formulation to represent anisotropic damage evolution and softening in TPC laminates across multiple length scales.

-

Integration of molecular and experimental insights: Using nano-scale and micro-scale data to inform the physics-based parameters of continuum models.

-

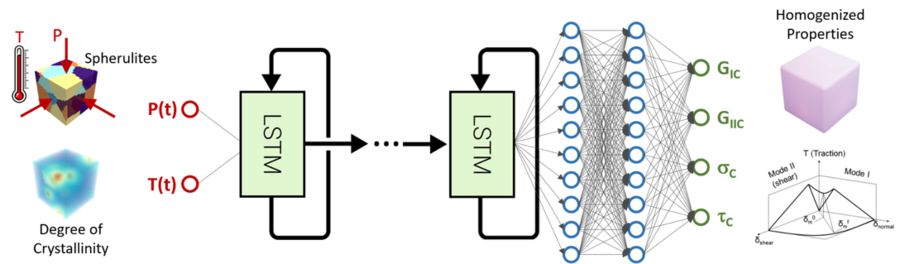

Machine-learning surrogate modeling: Building data-driven models to efficiently map processing conditions to structural performance indicators.

-

Optimization of processing parameters: Identifying processing windows that maximize interlaminar strength, toughness, and structural reliability.

Funding

German Research Foundation (DFG)

U.S. National science foundation

International cooperations

Professor Gregory M. Odegard, PhD

Brett A. Bednarcyk, PhD

Evan J. Pineda, PhD