Developing crossover austenitic stainless steel based on scrap recycling via forward experimental and numerical high-throughput assesssment of P-S-P linkages and inverse data-driven design

The production of metals and steel is a major driver of CO₂ emissions and raw material consumption. The priority program SPP 2489 “DaMic - Data-driven Alloy and Microstructure Design of Sustainable Structural Metals” addresses this challenge directly: its goal is to develop recycling-based metal alloys whose mechanical properties are comparable to those of conventional materials. The program combines materials science and applied mechanics to enable resource-efficient, high-performance metals for industrial use.

A central focus of the program is the development of austenitic crossover stainless steels that can be produced entirely from recycled metal scrap. They offer a resource-efficient and sustainable solution for alloy manufacturing. However, due to their novel chemical composition, they also give rise to microstructures with previously unknown properties.

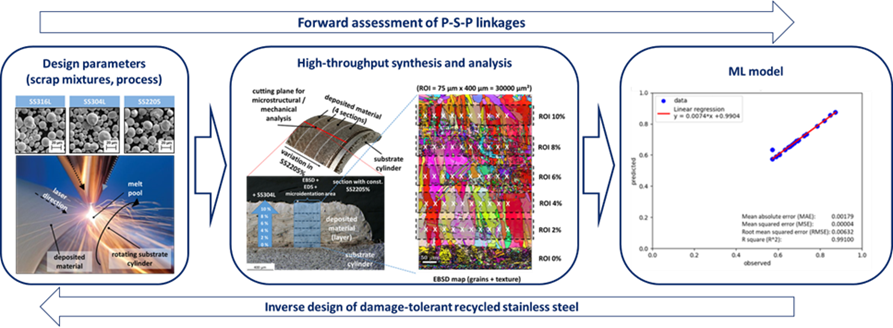

The aim of our project "Developing crossover austenitic stainless steel based on scrap recycling via forward experimental and numerical high-throughput assesssment of P-S-P linkages and inverse data-driven design" is therefore to investigate the influence of impurities on the microstructure and the mechanical properties. To achieve this, a novel failure zone homogenization scheme will be developed to enable the transformation from the micro- to the macroscale for metallic microstructures. This approach will cover localization of progressive damage as well as debonding of grain boundaries.

Subsequently, synthetic 3D microstructures are generated from the geometric data obtained by Professor Dr.-Ing. Christian Haase’s team. High-throughput sample fabrication techniques are employed in this process, followed by a quantitative evaluation of the process–structure–property relationships. Finally, an inverse design strategy will be applied to develop new, optimized alloy compositions.

Funding

German Research Foundation (DFG)

Cooperation

Institute of Material Science and Technology at TU Berlin:

Materials for Additive Manufacturing